6S method

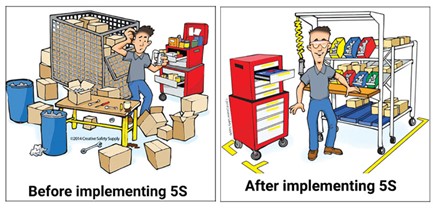

The 6S method is a workplace improvement process and assists in maintaining productivity and safety in the workplace. The six steps of the 6S method are: sort, systematize, clean, standardize, self-discipline and safety.

- Seiri (Sort

- Seiton (Set in order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain)

- Safety

Seiri (Sort)

Unnecessary tools and materials are identified and sorted out. This makes the workplace more organized and creates more space for needed work materials.

Seiton (Set in order)

A system is introduced for arranging the required work materials. Required tools and materials are arranged so that they can be accessed quickly and easily. The frequency of use as well as the order of use of the materials is taken into account.

Seiso (Shine)

The own workplace and work utensils are cleaned. The cleaning of the work equipment also serves to identify deficiencies as well as potential threads. Thus, a safe and hygienic working environment is created.

Seiketsu (Standardize)

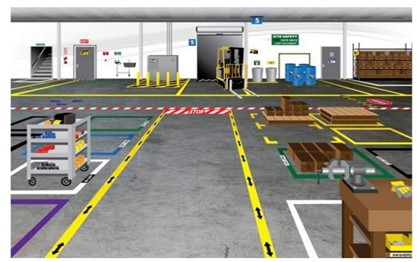

All workplaces are standardized Make it obvious where things belong, using lines, label signs, Shadow boxes, Shadow boards ect.

Shitsuke (Sustain)

Compliance with the above rules is to become a habit. Likewise, the rules are to be constantly reviewed and improved in order to achieve the best possible benefits.

Create rules, guidelines, cleaning charts, actions lists etc. using display boards, newsletter’s and give recognition to sustain successes.

Safety

To ensure safety in the workplace, potential sources of danger are searched for. After identifying the sources of danger, potential measures are defined and implemented to minimize the danger and increase safety.